Farmer Boy Creamery creates fresh, digestible milk in Dorchester

BY NEAL HOGDEN

TRIBUNE-PHONOGRAPH

“America’s Dairyland” is a nickname that Wisconsin has held for over a century. The term started being put on Wisconsin license plates in 1942 to honor the dairy industry and the cultural impact that Wisconsin farmers had instilled in the state’s economy.

It still rings true today. “America’s Dairyland” is producing more and more milk each year and reached a record high of 32.1 billion pounds of milk last year. So where does all the milk go after the more than 1.2 million cows produce it? Some of it goes to major milk producers that pasteurize and homogenize their milk to make it the “cookie cutter” product you think of when you think of milk.

However, milk has undergone a transformation globally over the past 10-20 years. Variants of milk such as oat milk, soy milk and almond milk all derive from plants, but some of the changes behind the milk-making process still keep the cow involved in central Wisconsin.

Located outside of Dorchester, Farmer Boy Creamery is taking a new spin on milk and bringing it virtually straight from the cow to the shelves of local grocery and convenience stores. Farmer Boy Creamery is run by Clifford Hoover and Leland Zimmerman who built the creamery inside of an existing building on Leland and his wife Carolyn’s homestead.

The name of the creamery, “Farmer Boy Creamery,” pays homage to Hoover and Zimmerman’s background growing up as farmers. Their logo displays a sketch of a farm with a silhouette of a farmer boy that was created by

_______.___ ___ _____________ ____________________________________..__._______ _________ ___________._ _________.________________________ ___________________________.__ _!_ _'_.___________#____

NEAL HOGDEN/TRIBUNE-PHONOGRAPH Clifford’s wife, Thelma.

Zimmerman said he grew up in Missouri but after his family moved to Wisconsin in 2017, he began working on a Christensen farm with Hoover. Even while living in Missouri, Zimmerman worked on a farm and said milking cows and managing a dairy herd was something that he spent a majority of his life doing. Zimmerman had dreamed of bottling milk for a while already but wasn’t sure where to start.

In the Fall of 2022 Zimmerman and Hoover started talking to Clarco (a milk broker) and they were willing to supply the duo with milk. Then, a local place came available and everything fell in place from there.

In May of 2023, he and Carolyn moved to a home four minutes west of Dorchester and started their own business.

The first order of business was to build a creamery. An existing building that had been used as a wood working shop was converted into a food-safe environment. Zimmerman said the building conversion was the most diffi cult part of the process when starting the business.

“It was originally a wood shop and we just put the walls in. It’s definitely not just your regular sheeting on the walls. They are required to be smooth and washable,” Zimmerman said.

He also said a lot of electrical work had to be done in order for the upscaled building and industrial equipment to have the power it needed.

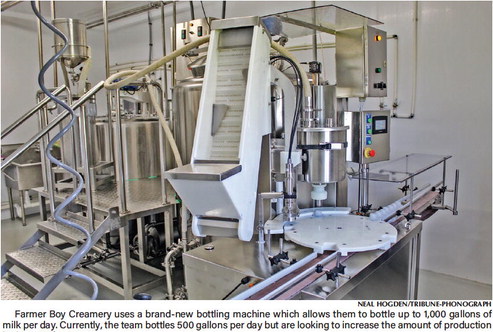

Zimmerman didn’t want older equipment to start out the creamery due to the fact that it could possibly make it harder to pass the state’s inspection. Therefore, he ordered brand new, stainless steel machinery from Pennsylvania and Israel for the creamery. He then had to wait 6-8 months for the machines to be built and delivered. He said it has been quite the investment but it was a necessary one to take to get the business started out on the right foot.

Zimmerman and Hoover spent two days at the University of Wisconsin - River Falls to get their pasteurizer license, and Zimmerman spent a day in Eau Claire getting his license to test for antibiotics in the milk.

“It’s definitely been a challenge to jump over all the hurdles with the state,” Zimmerman said. “But they’ve been really good to work with.”

Behind the scenes, he said there is a lot of paperwork that needs to be kept in order to keep track of which milk is going where.

“If someone gets sick and calls the state, we have two hours to figure out where that batch of milk is,” Zimmerman said.

Next, the duo of Zimmerman and Hoover had to figure out what kind of product they wanted to put out–something to set them aside from the competition. Growing up on a farm, the Farmer Boys were used to getting milk from the tank and did not care for the store bought milk.

Continued on page 21

________. ________ __ _ ______________.________________________._ _______.__._________.___________._ _. __________ __________ ____________.____ _ _______._ _______ __________.._____._______ ________.____. __._____.__ ____________ ______

NEAL HOGDEN/TRIBUNE-PHONOGRAPH Farmer Boy Creamery

________. ___ ____ _

So much of the milk on the shelf is pasteurized with using Ultra High Temperature (UHT) where the milk is heated to 282 degrees for a couple seconds. Zimmerman said he wanted a product in which consumers can taste the difference between their process and other milk bottlers’ processes.

First, they connected with Michael Martin, a local farmer who owns a herd of dairy cattle that are A2/A2 certified. Typical milk contains both the A1 and A2 betacasein protein. A2/A2 certified cows are bred to produce milk that only contains the A2 variant of beta-casein protein which is better for the digestive health of those who consume the milk. Zimmerman said A2/A2 milk does not taste or look differently than milk with both A1 and A2 proteins.

“We’ve had quite a few comments on that,” Zimmerman said. “Some people were able to drink milk that normally couldn’t.”

The second way the Farmer Boy product is set apart from others is the way they produce it. Zimmerman and Hoover use a low-heat, vat pasteurization process which helps retain the nutritional value and flavor of the milk. According to Working Cow Dairy, low temperature vat pasteurization heats milk to kill unwanted bacteria but preserves the healthy Omega-3 fatty acids, essential minerals, and fat-soluble vitamins A, D3, and K2.

Finally, Farmer Boy Creamery does not homogenize its milk. Homogenization is a process in which milk is pushed through a screen with small holes at high pressure that breaks up the fat molecules and produces a stable emulsion in which the milk doesn’t separate.

Because Farmer Boy Creamery does not homogenize its milk, their product is considered creamline, meaning the cream will rise to the top when the milk settles. In order to get the cream mixed back into the milk, the consumer must shake it well every time they use it. Zimmerman said he knows some people who like to skim the cream off the top and use it in their coffee as well.

“We currently just do whole milk, because that is the easiest. The vitamins are in the cream so if we do 2% milk the state requires us to add Vitamins A and D back in,” Zimmerman said.

When all is said and done, the white milk has no added ingredients, and the chocolate milk has eight, including a cocoa powder that comes from Ohio. Ingredients in the chocolate milk include: whole milk, sugar, cocoa (processed with alkali), dextrose, cornstarch, salt, carrageenan and natural vanilla.

The bottling and distribution process

Every week, Farmer Boy Creamery picks up a shipment of A2/A2 milk on Wednesday morning with their little milk truck. The state requires Zimmerman and Hoover to unload the milk inside a building and the creamery does not have the room to unload a big truck, so Zimmerman and Hoover bought a small Mitsubishi truck and mounted a 800 gallon tank on it that originally came from Yellowstone Cheese. The tank was all set up with a pump so it did not need much work, Zimmerman said. Zimmerman puts the milk through the pasteurization process and by Wednesday evening, it is in bottles. Then, on Thursday, the Zimmermans load up their delivery van and take milk all over central Wisconsin.

The milk goes from cow to shelf in two days making it some of the freshest milk available. Zimmerman said the milk has a shelf life of 18 days which is what the state recommends.

Zimmerman said they bottle roughly 350 gallons of milk (150 gallons of chocolate milk and 200 gallons of white milk) each week and have the potential to do much more.

“We could do roughly 1,000 gallons per day,” Zimmerman said. “We’ve got pretty good room for growth here.”

The creamery sells whole milk and whole chocolate milk which is available in 8 oz., 16 oz., half gallon and gallon- sized containers and is available at Abbyland Truck Stop and Cloverdale Country Store in Curtiss, Martin’s Fresh Market and Creekside Convenience Store in Owen, Sunny Side Produce in Stanley, Farmers Pantry in Thorp, Yellowstone Cheese in Cadott, Village Market in Spencer and at the Medford County Market. Zimmerman said they have room to grow and are more than willing to add retailers to their list of distributors. He said their prices are currently competitive with other milk distributors.

“We’re trying to stay competitive with our prices so the people on a tight budget can afford it. Which on a smaller scale like this, it’s harder to, just because we aren’t as efficient as some of the bigger companies,” Zimmerman said. “As we ramp up production, our efficiency will improve too.”

Hoover is still currently milking on a farm close to Abbotsford and Zimmerman is holding a part time job, until they can go full-time with the creamery.

Zimmerman said that growth might be on the horizon as Farmer Boy Creamery has received a few requests for milk in glass bottles. He said the duo might consider adding glass bottles down the line but they do not have a bottle washer in the facility so it might have to wait.

The creamery is located at W1658 County Hwy. A, west of Dorchester and Zimmerman said they have a refrigerator in their creamery building where people can go in and purchase their own milk six days a week by leaving cash behind.

Today, the Zimmerman’s children help out here and there with tasks around the house and in the creamery. Lyndon, Katrisha, Jevon and Charity all have different tasks they can do to help get the milk processed, bottled and shipped. Sometimes, that means they are stacking crates. Other days, it might be keeping Leland company, but they always are available to help when needed.

If you have questions about the milk or would like to be a distributor of Farmer Boy Creamery milk, you can reach Leland and Clifford by phone at 715-721-0766 or by email at farmerboycreamery@gmail.com.

________. ____ _________ _______________ _ __ _______ _______.__ ____________________ ___________.__ ___ __ _ _.____ ___ _ ___ __ _____ ___________ _!.__________ ____ __._________ _.__'_#_ __ __.______

NEAL HOGDEN/TRIBUNE-PHONOGRAPH