Making time for maple syrup

By Kevin O’Brien

Not much will stop Ben and Suzanne Stanfley from making maple syrup.

Whether trudging through a foot of snow or fixing a break in a sap line, the couple are always working to keep the syrup flowing. Even the birth of a child, during the heart of this year’s maple syrup season, barely slowed them down.

“Suzie was in the hospital for awhile there, so it was kind of a scramble,” Ben said.

“Ben ended up cooking two times while I was in the hospital,” Suzanne added.

The day after their son, Walter, was born, Ben and his dad, Vernon, managed to cook seven barrels.

Stanfley Farms, located about eight miles north of Owen, has been producing highquality maple syrup for the past six years, growing from a small start-up with a few dozen trees to an operation with a total of 120 acres of tapped trees between two locations.

The Stanfleys started off by leasing land from a friend, Jim Bauer, and tapping about 60 trees. Like most people who get into syruping, they began by hanging bags before moving to gravity lines and then investing in a full vacuum system.

“The first year we started was the big snow year of 2018, so that was a struggle getting going,” Ben said. “That first year, I think we got up to just over 3,000 taps.”

They bought their home on Elm Avenue three years ago, built a large sugar shack and established a network of trails and vacuum tubes in the 60 acres of woods north of their house. They’ve expanded to a total of 8,000 taps, but it hasn’t been easy, though.

“Our first year here, cooking and everything, ended up being a bad year,” he said. “Last year, it was slightly below average, which wasn’t great, but then this year has been a good year.”

At the start of this month, Ben said they were at about 80 percent of a full harvest. They had one of their biggest days – cooking 1,600 gallons of sap into 6.5 barrels of syrup – in the first week of April.

“That’s almost 10 percent of the crop we’re looking for in one day,” he said.

The amount of syrup produced by the small, family-run business has steadily increased over the past three years, starting with 33 barrels in 2023 and growing to 50 last year. As of April 4, they were on track for 60 barrels this year.

“Besides two years ago, we’ve had 20 gallons per tap or higher every single year,” he said. “We’ve been fortunate that way, whether they were just great years or what.”

Ben, who is Taylor County’s highway commissioner, has a degree in engineering, which helps with running slopes and determining the right-sized pumps. Suzanne, Taylor County’s director of human services, manages to balance her day job with being a new mother and working to make maple syrup.

Even though the weather whiplashes between snow and rain, and the ground is either frozen or muddy, Ben said those who are really into maple syruping like this time of year.

“It’s kind of that transition between winter and summer,” he said. “There’s not a lot to do. It’s nice to get out in the woods and be active. I enjoy being out in the woods and spending time with my family.”

One way in which Stanfley Farms has distinguished itself in Central Wisconsin’s crowded maple syrup market is by adding different flavors to their syrup, including vanilla, cinnamon, blueberry and apple. The blueberries come fresh from local farms such as Harder’s Blueberries south of Greenwood and Nelson’s Berries north of Medford.

Infusing these additives into their syrup has a been a process of trial-and-error to make sure the flavors aren’t overwhelming.

“It’s changed drastically from how we originally started until now,” he said.

Vanilla and cinnamon have proven to be their most popular flavors by far, but the blueberry and apple varieties also have their fans.

The Stanfleys have also invested in top-ofthe- line equipment, buying a Lapierre brand evaporator, tanks and other accessories from Midwest Maple Supply in Athens, which also bottles and sells their syrup. Their vacuum lines pump into a 7,000-gallon sap tank, located next to a 6,000-gallon reverse-osmosis water tank. Eventually the sap ends up in a 1,000 gallon bulk tank that was originally used at the dairy farm near Lancaster run by Ben’s grandfather, who passed away last fall.

“That’s very special to me,” he said. The workhorse of their operation is a stainless steel evaporator with a 4-by-16 foot pan, which helps them boil down sap into syrup in a shorter period of time.

See STANFLEY/ page 18

NEW ADDITION - Suzanne and Ben Stanfley stand next to their maple syrup evaporator with their newborn son, Walter, who was just two weeks old when this photo was taken. Their three-person maple syrup operation near Owen, which also includes Ben’s dad, Vernon, did not miss a beat when Walter entered the world during the busy season.

STAFF PHOTO/KEVIN O’BRIEN Stanfley

Continued from page 11

“Most of our equipment is a little oversized for the size that we are, just because we are so busy with our regular jobs and everything else,” he said. “I can’t be here and taking forever.”

For the first time this year, the Stanfleys are taking sap from smaller-scale maple syrup operations in the area, most of whom are just collecting what they can in bags.

“We didn’t know any of these people,” Suzanne said. “As we were cooking throughout the year, they just stopped and said ‘Hey, will you buy our sap?’” Another innovation that has helped their three-person operation is a monitoring system that keeps tabs on the sprawling collection system in the woods, so if there is a leak somewhere, Ben, Suzie and Ben’s dad will all get text messages sent to their phones.

“As soon as something does happen, we can get on it right away,” Ben said.

Still, when it comes to the success of their business, the Stanfleys said it comes down to old-fashioned “hard work and determination” and developing good partnerships with businesses and people like their neighbor, Jim.

Suzie said she and her husband are out in the woods every Saturday and Sunday from as early as November to as late as May, getting everything prepped, maintaining the flow of sap and making repairs as needed.

“You’ve got two months out of the year to make your profit, so you’ve got to be ready for it, and work in the offseason to get everything fine-tuned and ready,” Ben said.

It’s ultimately worth it for the Stanfleys, who not only sell syrup but add it to everything from coffee to ice cream – not to mention French toast for family breakfasts. Their older son, Winston, is almost three and already loves his parents’ signature products.

While it’s not for everyone, Ben said maple syruping can be a great hobby or even a lucrative business.

“What I would say is just start off small and make sure you like it,” he said. “More than likely, you’ll quickly become addicted to it, especially if you like the outdoors and being active.”

Stanfley Farms syrup is sold at a few local stores, including CreekSide Convenience in Owen and WCCN’s Pavilion Cheese, Wine & Gifts in Neillsville, and at Whistling Well apple orchard in Hastings, Minn. and the Vesperman Farms pumpkin patch in Lancaster.

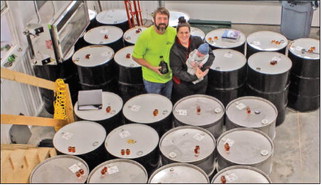

KEEPING BUSY - The Stanfleys stand amongst several barrels of their maple syrup. The tiny jars on top of each barrel are samples used for testing.

STAFF PHOTO/KEVIN O’BRIEN