Pettit family evolves with new technology

In the past few years, people all across the country have found a desire to pursue more natural products in their diets and to eat healthier, raising the demand for foods such a maple syrup. To meet this growing demand, the Pettit Family is adopting new technology to use alongside their traditional methods of making maple syrup.

A lot has changed for the Pettits over the years as they have worked to create their brand of Pettit Family Traditional Maple Syrup. Starting nearly 20 years ago at their residence at W1018 Starr Road in Chili, Wade Pettit said they have continued to grow over the years and evolve their craft, going from cooking sap over a fire pit made out of cinderblocks to an enterprise that now operates two large evaporators out of a new facility they built in the past year.

“Sixteen years ago I remember making syrup on our land,” he said. “We went from making syrup over a cinder block fire pit to a small sugar shack and then the upgraded facility that was completed within the last year. We did all of the work ourselves. We built it, and it took us seven months to get it done.”

The wood pellet-fired evaporator is piece of technology virtually unknown in this area of the United States. More commonly used in the eastern states such as Vermont and New Hampshire and also in Canada, Pettit said this evaporator is different from the ones traditionally used in Wisconsin to make syrup because of its fuel source. “We wanted to stay with a renewable fuel source and wood pellets was the answer. The thought of cooking maple syrup with gas or fuel oil was not very appealing nor was the volatility of that type of fuel market.

“The RO process removes water from the sap concentrating the sugars and when run through the pellet evaporator, we can make a barrel of syrup in an hour versus making a barrel in 12 hours without. It takes longer the traditional way to completely get the water out of the sap.”

Compared to the traditional method which requires long stints of boiling sap over a wood fire evaporator, Pettit said the pellet evaporator requires much less manpower to operate. Instead of wood, the evaporator automatically feeds pellets through an auger system into its burners. By using this evaporator in conjunction with their traditional cooker, he said it allows them to keep up with the sheer amount of sap they process each year.

“With the traditional evaporator, you need to add fuel every 40 minutes,” he said. “It helps, not only labor wise, but with the transporting and storage of the wood supply. Last year we burned through 250 bundles of wood. It would be very hard on a guy to try to run two of them (wood-burning evaporators). Last year we had cooked 15 straight days for 24 hours per day. With the pellet-fired, you get it fueled up and it runs by itself with continuous monitoring of sap levels in the pans and finished syrup quality. There is no throwing wood in. It automatically feeds the pellets into the burner and burns 500 pounds of pellets per hour.”

Even though the process used by the new evaporator is quicker than the traditional model and requires much less manpower and supervision, Pettit said the cost of running the pellet-fired evaporator is much higher than the traditional method. Pellets -- especially in the amounts required to run the evaporator -- are much harder to come by in Wisconsin, making it financially impossible to produce syrup using this method alone.

“It runs at a cost of about $60 per hour, the price per gallon of syrup is not feasible,” he said. “Part of the problem is the supply of pellets, which is limited. There are not a lot of places that sell pellets that can deliver in bulk like we need.”

By using both the RO and pellet-fired evaporator for the of processing the sap into maple syrup, Pettit said they are able to process all of the sap that they get from both their own trees and from others who have their own sap brought over to be processed. Each year, he said they tap 3,000 trees of their own and receive even more sap to process from Amish and other locals, which totals to about 21,000 taps.

“We do 3,000 taps on our own, about 1,800 bags and 1,200 trees on a line,” he said. “We pick up sap from people with our big sap hauler and a lot of our sap comes from the Amish. Most often the Amish and many other people have us cook on halves where they are given half of the syrup produced. Only the traditional syrup is returned to people and it is the only syrup that we bottle as there is a slight difference in taste. Traditional syrup doesn’t use a reverse osmosis (RO), and has a longer cook time, which means there is more time on the pan for caramelization of the sugars,” he said.

This interconnectedness with the families that live nearby, Pettit said, is an important aspect of Pettit’s Traditional Family Maple Syrup. When anybody walks through the door into their facility where they make their syrup,

he said it is important for them to feel they are at home, are valued for their contributions and are a part of their maple family.

“I think it is huge,” he said. “We have those that we call our ‘Maple Family’, those that have provided us with sap, they are a part of our family. You see it when people come in feeling welcome and comfortable to observe the process. We would want them to feel like they are a part of our family. Everyone is welcome to come by and bring mom and dad, or grandpa and grandma to watch the process and have some ice cream and hot maple syrup.”

During the next few years, Pettit said their goal for the Pettit Traditional Maple Syrup brand is to continue to grow and make the process of collecting and producing syrup more efficient and easier on the trees. “Our plan is to put in more taps on a line system, which is up all year round,” he said. “We have ways to install lines that don’t have leaks. It’s kind of a new thing that allows us to fuse the taps to the mainlines to get an air tight seal. Doing more lines means less bags, which are more labor intensive and harder on the trees. Lines are better because there is no driving through the woods to get the sap and damaging tree roots. It doesn’t hurt the trees.”

By adapting new technology into their maple syrup production, Pettit said they will be able to continue taking on new sap suppliers. Desire for maple syrup has only gone up since the COVID-19 pandemic, and by innovating new ways to retrieve sap and give customers a good product, they will be able to provide people what they want.

“They say demand for syrup is up 20 percent from before,” said Pettit. “COVID has driven a lot of people away from processed food and towards real food and real syrup. That is partially why the demand is going up. “

There is a lot to this process. It is all about learning from experience and often doing some research. “Visitors have so many questions as to why there is different colors of syrup or what makes the syrup through a channeled pan?”

Producing maple syrup is a real passion for the Pettit family as all of the family is involved is some aspect from tapping to cooking to bottling and labeling. Understanding the all aspects of the process, the labeling requirements and keeping a clean licensed facility that produces a quality maple syrup is very important to everyone in the Pettit family.

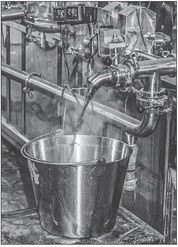

SYRUP IN A BUCKET- Freshly cooked sap pours out of the cooker into buckets that will take the sap to the next stage of production where it is checked for quality and bottled.

FAMILY- Members of the Pettit Family are (from left) Billy Barth, Joan Martin, Dominic Gerretsen, Ari Gerretsen (held), Cassie Pettit, Brenda Pettit, Wade Pettit, Kenny Pettit and John Martin. The family works together every year to make their traditional maple syrup.