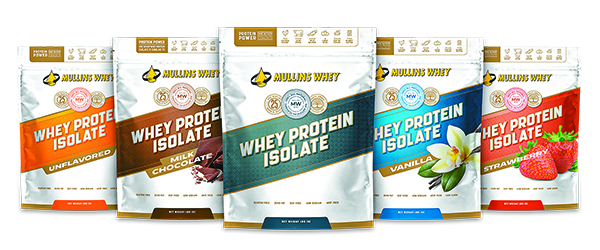

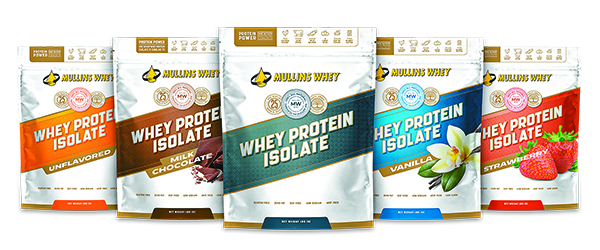

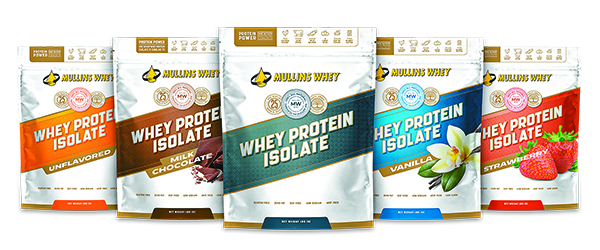

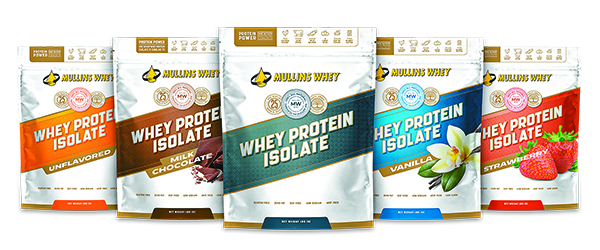

Leading the whey: Mullins produces dairy-based nutrition products

By Saskatoon Damm, The Star News

Wisconsin is the dairy state, and that title extends beyond just cheese and milk.

I...

By Saskatoon Damm, The Star News

Wisconsin is the dairy state, and that title extends beyond just cheese and milk.

I...